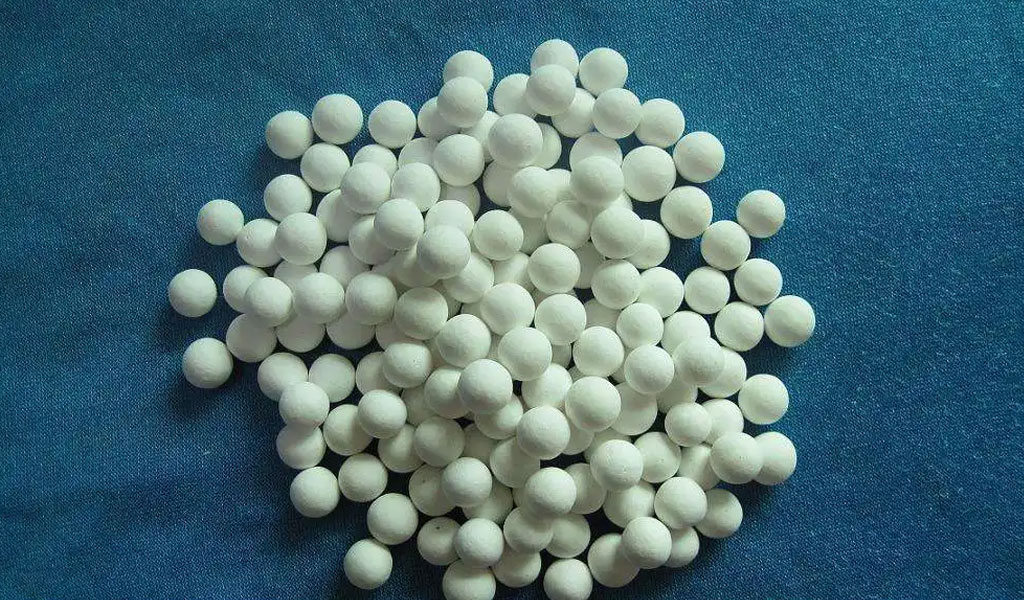

The 99.8% alumina ceramic is made of white alumina powder with a purity of 99.8%. The powder is mixed with a small amount of oxides such as Fe2O3 and Na2O. After alumina material molding and sintering, it becomes a white solid insoluble in water, odorless and tasteless. , High hardness, easy to absorb moisture but not deliquescence (burned does not absorb moisture). The density of 998 alumina ceramics is between 3.8-3.9g/cm3, its melting point is 2050℃, and its high temperature resistance is 1700℃. The compressive strength is 2550Mpa and the dielectric constant is 9.85. Compared with 95 porcelain, 99 porcelain and 995 porcelain, 998 alumina ceramics have stronger insulation properties and compressive strength. In terms of thermal conductivity, the thermal conductivity of 998 alumina ceramics is 34-39W/m.k, which is also stronger than other types of aluminum ceramic. It is a thermally conductive insulating material with excellent performance.

There are still few companies using 998 alumina ceramics in the market. Relatively speaking, it is suitable for some high-end industries, such as glass slides, hydrochloric acid laboratories, etc. In addition, its cost is higher than 95 porcelain and 99 porcelain. 998% of the powders used by Pintejin Ceramics come from abroad.

99.8% Alumina Ceramic Technical Parameters

| Performance | Unit | 998 Alumina AL2O3 |

| Bulk density | g/cm3 | 3.8~3.9 |

| Rockwell hardness | HRA≥ | 82~86 |

| Flexural strength | Mpa≥ | 300 |

| Maximum use temperature | °C | 170o |

| Linear expansion coefficient | ×10-6/rC | 7.15-7.67 |

| Dielectric constant | Er(20°C, 1MHz) | 9.85 |

| Dielectric strength | kV/mm | 23.6 |

| Dielectric loss | tan6×10-4,1MHz | 2.5 |

| Volume resistivity | -cm(10oC) | 9.2*1016 |

| Compressive strength | Mpa2 | 2556 |

| Flexural strength | Mpa≥ | 314 |

| Elastic Modulus | Gpa | 358 |

| Poisson’s ratio | l | 0.2 |

| Thermal Conductivity | W/mK(20°℃) | 34-39 |

| DC breakdown strength | kV/mm | 43.7 |

| Tensile seal strength | Mpa | 104.4 |

| Acid and alkali corrosion resistance | l | powerful |